Helical Gear Hardness . Gear designers decide specifications in accordance with factors like torque, rotation and expected lifetime. Gear materials and heat treatments are important factors to decide specification including hardness of all types of gears. The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in. Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. Powder metallurgy is a proven technology to produce high strength gears for the automotive industry. Strength of gears depends on the breakage durability or friction durability. Notice that parameters pertaining to. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth as well as pitting failure of. You can check them in this page.

from www.alibaba.com

You can check them in this page. Gear materials and heat treatments are important factors to decide specification including hardness of all types of gears. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth as well as pitting failure of. Gear designers decide specifications in accordance with factors like torque, rotation and expected lifetime. Strength of gears depends on the breakage durability or friction durability. Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. Notice that parameters pertaining to. Powder metallurgy is a proven technology to produce high strength gears for the automotive industry. The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in.

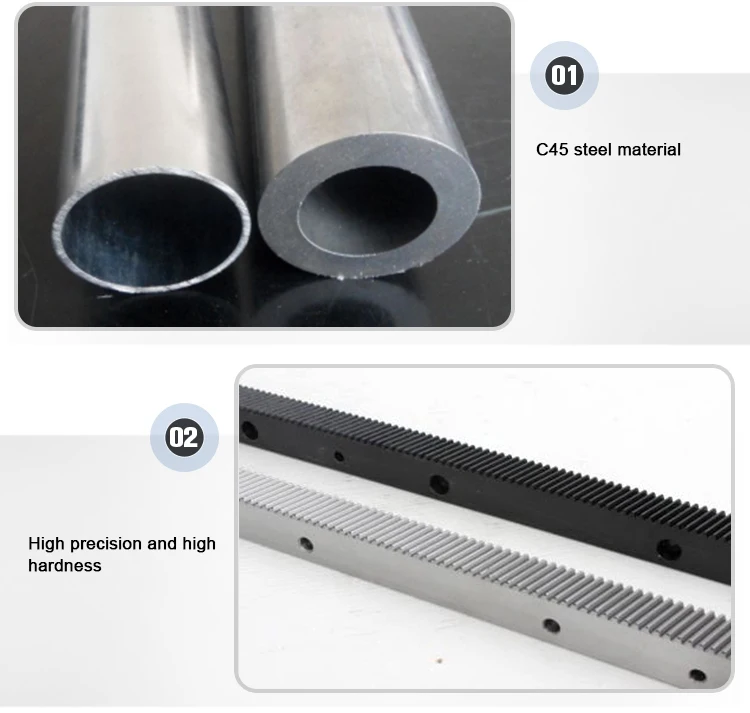

High Hardness Straight Teeth Linear Gear Rack Buy Helical Gear Rack

Helical Gear Hardness Notice that parameters pertaining to. Gear designers decide specifications in accordance with factors like torque, rotation and expected lifetime. Gear materials and heat treatments are important factors to decide specification including hardness of all types of gears. Powder metallurgy is a proven technology to produce high strength gears for the automotive industry. Strength of gears depends on the breakage durability or friction durability. Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. Notice that parameters pertaining to. The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in. You can check them in this page. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth as well as pitting failure of.

From cnhfgear.en.made-in-china.com

OEM Steel Hardness Helical Worm Rack Straight Spiral Spur Bevel Gears Helical Gear Hardness The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in. Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of. Helical Gear Hardness.

From shopee.ph

XI High Hardness Strength Die Steel Material Helical Gear for Mini V1 Helical Gear Hardness Strength of gears depends on the breakage durability or friction durability. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth as well as pitting failure of. Gear materials and heat treatments are important factors to decide specification including hardness of all types of gears. You can check them. Helical Gear Hardness.

From www.liebherr.com

Gear shaping of double helical gears Liebherr Liebherr Helical Gear Hardness Gear materials and heat treatments are important factors to decide specification including hardness of all types of gears. You can check them in this page. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth as well as pitting failure of. Powder metallurgy is a proven technology to produce. Helical Gear Hardness.

From goldgun.en.made-in-china.com

Hardness Helical Gear Reducer China Gear Speed Reducer and Helical Gear Hardness Notice that parameters pertaining to. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth as well as pitting failure of. You can check them in this page. Powder metallurgy is a proven technology to produce high strength gears for the automotive industry. Gear materials and heat treatments are. Helical Gear Hardness.

From zdcpucn.en.made-in-china.com

Different Colors High Hardness POM Helical Gear/ABS Chain Gear/Nylon Helical Gear Hardness Powder metallurgy is a proven technology to produce high strength gears for the automotive industry. Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. Strength of gears depends on the breakage durability or friction durability. You can check them in this page. Gear designers decide specifications in accordance with factors like. Helical Gear Hardness.

From www.indiamart.com

Mild Steel Industrial Double Helical Gear, Rs 500 /piece R.V Industries Helical Gear Hardness Gear materials and heat treatments are important factors to decide specification including hardness of all types of gears. You can check them in this page. The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in. Notice that parameters pertaining to. Powder metallurgy is a proven technology to. Helical Gear Hardness.

From www.walmart.com

Helical Gear Upgrade Gear High Hardness Strength Die Steel Material Helical Gear Hardness Notice that parameters pertaining to. The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in. Strength of gears depends on the breakage durability or friction durability. You can check them in this page. This chapter is devoted primarily to analysis and design of spur and helical gears. Helical Gear Hardness.

From www.pinterest.fr

Terminology of Gear Tooth More in Mechanical Helical Gear Hardness You can check them in this page. Notice that parameters pertaining to. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth as well as pitting failure of. Gear designers decide specifications in accordance with factors like torque, rotation and expected lifetime. Powder metallurgy is a proven technology to. Helical Gear Hardness.

From www.aliexpress.com

FYSETC Helical Gear Upgrade Gear High Hardness Strength Die Steel Helical Gear Hardness Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth as well as pitting failure of. Strength of gears depends on the breakage durability or friction durability. You can check them. Helical Gear Hardness.

From khkgears.net

Bending Strength of Spur and Helical Gears KHK Helical Gear Hardness Gear designers decide specifications in accordance with factors like torque, rotation and expected lifetime. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth as well as pitting failure of. Strength of gears depends on the breakage durability or friction durability. Powder metallurgy is a proven technology to produce. Helical Gear Hardness.

From www.liebherr.com

Gear shaping of double helical gears Liebherr Liebherr Helical Gear Hardness Gear materials and heat treatments are important factors to decide specification including hardness of all types of gears. Notice that parameters pertaining to. You can check them in this page. Strength of gears depends on the breakage durability or friction durability. Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. Gear. Helical Gear Hardness.

From www.liebherr.com

Gear shaping of double helical gears Liebherr Liebherr Helical Gear Hardness Notice that parameters pertaining to. Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in. Gear materials and heat treatments are important factors to decide specification including hardness of. Helical Gear Hardness.

From www.iqsdirectory.com

Helical Gear What Are They? Types, Uses & Considerations Helical Gear Hardness Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in. Gear designers decide specifications in accordance with factors like torque, rotation and expected lifetime. Notice that parameters pertaining to.. Helical Gear Hardness.

From www.alibaba.com

High Hardness Straight Teeth Linear Gear Rack Buy Helical Gear Rack Helical Gear Hardness Strength of gears depends on the breakage durability or friction durability. The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in. Notice that parameters pertaining to. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth. Helical Gear Hardness.

From www.tradeindia.com

Stainless Steel Pinion Shaft Hardness Rigid at Best Price in Ludhiana Helical Gear Hardness Strength of gears depends on the breakage durability or friction durability. Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. Gear materials and heat treatments are important factors to decide specification including hardness of all types of gears. Gear designers decide specifications in accordance with factors like torque, rotation and expected. Helical Gear Hardness.

From www.alibaba.com

High Hardness Straight Teeth Linear Gear Rack Buy Helical Gear Rack Helical Gear Hardness Gear designers decide specifications in accordance with factors like torque, rotation and expected lifetime. The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in. Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. This chapter is devoted primarily. Helical Gear Hardness.

From www.youtube.com

Cutting Helical Gears on the Horizontal Milling Machine Setting up the Helical Gear Hardness Powder metallurgy is a proven technology to produce high strength gears for the automotive industry. Helical gears are compatible to mesh if the normal module, normal pressure angle, and helix angle are matching. Notice that parameters pertaining to. Gear materials and heat treatments are important factors to decide specification including hardness of all types of gears. This chapter is devoted. Helical Gear Hardness.

From www.zhygear.com

Measuring conditions and steps for machining design of cylindrical Helical Gear Hardness The applications of both spur and helical gears can be the same, although because of the more gradual engagement of the teeth in. This chapter is devoted primarily to analysis and design of spur and helical gears to resist bending failure of the teeth as well as pitting failure of. Gear designers decide specifications in accordance with factors like torque,. Helical Gear Hardness.